Challenge & Context

Industrial manufacturing companies require reliable and efficient monitoring and control of their processes, necessitating the development of innovative and cost-effective solutions. The advent of the Industrial Internet of Things (IIoT) has made it possible to collect and analyse vast amounts of data. However, ensuring the reliability and accuracy of the data collected from a diverse range of smart, small-sized interconnected factory devices remains a challenge. To address this issue, the i4QP introduces Reliable Industrial Data Services (RIDS), a comprehensive suite of 22 innovative and cost-effective solutions. These solutions cover the entire data cycle, including sensing, communication, computing infrastructure, storage, analysis, and optimization.

With i4Q RIDS, industrial data can be efficiently managed, enabling real-time monitoring and control of manufacturing processes. It also provides simulation and optimization tools for continuous process qualification, quality diagnosis, reconfiguration, and certification, ultimately ensuring high manufacturing efficiency.

The journey towards achieving Zero-Defect Manufacturing (ZDM) presents several challenges. One such challenge is gathering data from common devices and industrial machines, while ensuring real-time data processing, seamless integration with existing platforms and services, support for common industrial standards and interfaces (e.g., OPC UA, MQTT, etc.), and accurate data visualization and monitoring to identify trends and detect potential abnormal behaviours in advance.

Among all the pilots in the i4QP, BIESSE, a renowned manufacturer of joinery, furniture, windows, doors, and wood building components since 1969, faced a specific challenge. They needed to ingest data and events from multiple woodworking machines communicating via the OPC UA protocol, which is the de facto standard in the automation market and Industry 4.0. This data needed to be directed to i4Q RIDS for further processing and analysis.

Specifically, BIESSE described their business pain as follows:

“On woodworking machinery, it is very challenging to keep the health of components under control, which can affect machine downtime, customer satisfaction, and costs.The i4QP aims to handle a large amount of data provided by OPC UA servers and the smart sensors on our CNC machines. Thanks to the implementation of i4Q RIDS, BIESSE can provide its customers new diagnostic tools and Industrial IoT services, to remotely monitor and manage their manufacturing systems more efficiently and to predict anomalies in advance.”

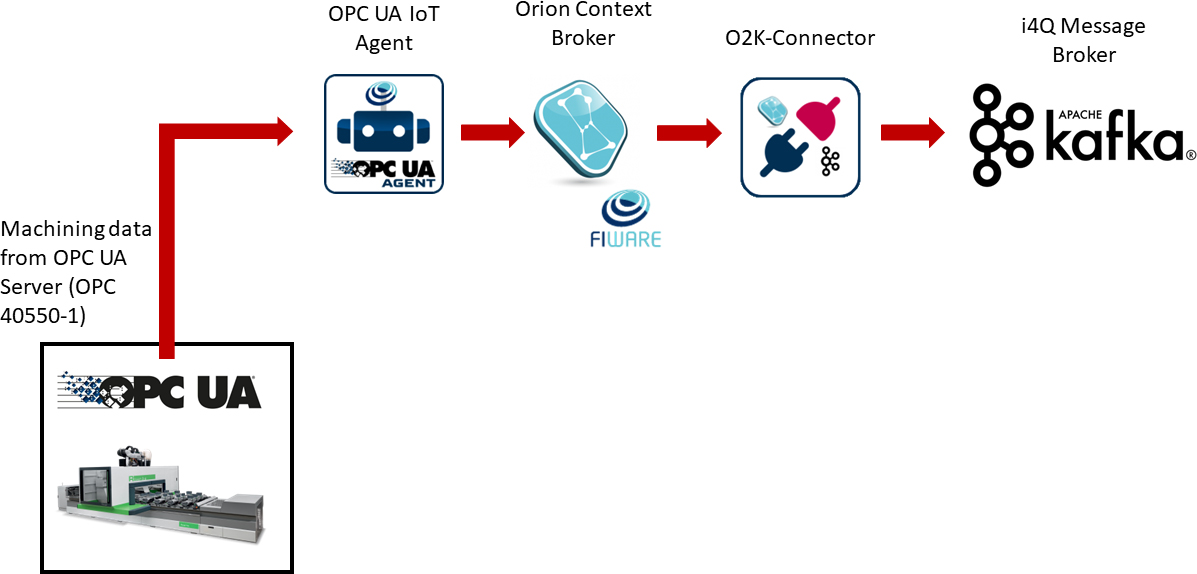

To achieve this objective, the FIWARE OPC UA IoT Agent has been proposed as a bridge to handle communication between the OPC UA machines and the NGSI interface of a FIWARE – Orion context broker. Additionally, a new companion tool called the O2K-Connector has been developed. This tool is designed to efficiently transmit data from the OPC UA field to the Apache Kafka-based i4Q RIDS, also known as the “i4Q Message Broker”, simplifying data distribution to other i4Q services.

Solution

The proposed solution aims to reduce idle times for data analysis, establishing a real-time ingestion pipeline for defect identification and failure recovery.

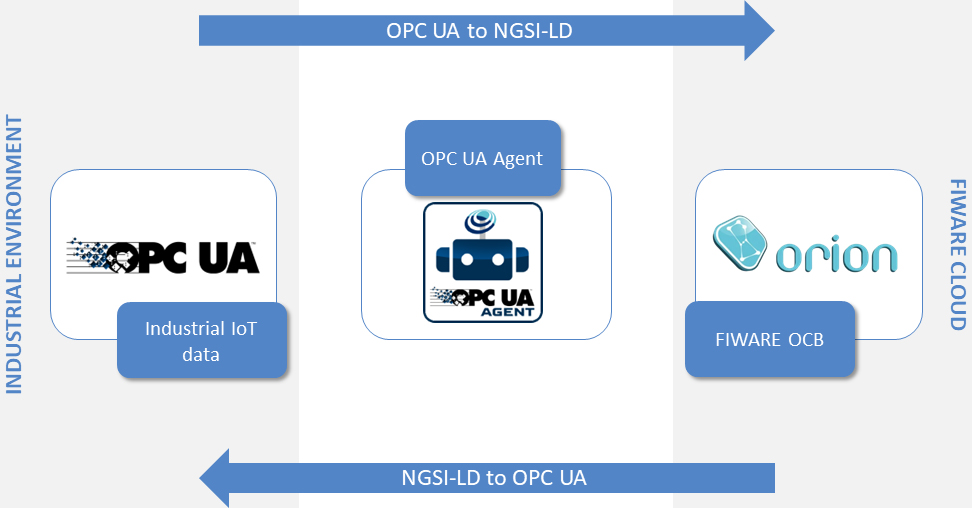

The IoT Agent OPC UA serves as a crucial intermediary, ensuring a robust connection between OPC UA servers and the FIWARE Orion Context Broker within the FIWARE environment. This integration is of paramount importance for industries interested in harnessing the full potential of the Industrial Internet of Things (IIoT) and enhancing their operational efficiency.

At its core, the IoT Agent OPC UA acts as a bridge, facilitating the seamless exchange of data and commands between OPC UA servers and the FIWARE – Orion Context Broker. Here’s an in-depth description of how this process unfolds:

- Data Source: OPC UA servers, responsible for collecting real-time data from industrial devices, machines, and sensors, adhere to the OPC UA communication protocol, which is known for its reliability and security.

- IoT Agent OPC UA: Positioned as a middleware component, and typically hosted on a dedicated server, the IoT Agent OPC UA establishes connections with one or more OPC UA servers. Its primary function is to bridge the gap between the OPC UA protocol and the NGSI (Next Generation Service Interface) protocol, which is the standard format used by the FIWARE – Orion Context Broker to manage IoT data.

- Data Mapping: The IoT Agent OPC UA receives data from the OPC UA servers and meticulously translates it into an NGSI-compliant JSON-LD format. This transformation involves associating context information with the data, making it semantically understandable for the Orion Context Broker.

- Data Transmission: After the data has been appropriately mapped, the IoT Agent OPC UA forwards it to the FIWARE-Orion Context Broker via HTTP or MQTT. The FIWARE – Orion Context Broker, a critical FIWARE component, receives and stores this contextual information. Additionally, it can carry out real-time processing, such as data filtering, aggregation, or the execution of predefined actions based on incoming data.

- Bidirectional Communication: One notable feature of this solution is its bidirectionality. In addition to data retrieval, users can send commands directly to the OPC UA server from the FIWARe – Orion Context Broker through the IoT Agent OPC UA. This bidirectional capability facilitates remote control and management of industrial assets and processes from within the FIWARE environment.

- Application Integration: IoT applications, dashboards, and services can seamlessly subscribe to context updates from the FIWARE Orion Context Broker. This allows for real-time monitoring, analysis, and control of industrial assets, all while benefiting from the semantic richness of NGSI data.

In conclusion, the IoT Agent OPC UA serves as a pivotal bridge, fostering seamless interoperability between the OPC UA standard prevalent in industrial settings and the NGSI-based FIWARE ecosystem. This integration empowers industries to efficiently collect, process, and act upon data from their operational technology (OT) systems, resulting in more informed decision-making, predictive maintenance, and the overall optimization of industrial processes. Additionally, the bidirectional nature of the solution enhances control and management capabilities, further amplifying its value in industrial applications.

Figure 1 . Technical Framework

How it works

The OPC UA IoT Agent has been reengineered from scratch to improve performances and capabilities. Furthermore, the functionalities of the OPC UA IoT Agent have been expanded to include support for a subset of real-world scenario OPC UA Companion Specifications right out of the box, such as OPC 40550-1 Woodworking Machines and OPC 40010-1 Motion Device Systems for Robotics.

An OPC UA Companion Specification defines an information model often referred to as “industry-standard models”, in which machines provide specific information about their status. The OPC UA Agent can automatically recognize the provided Companion Specification and begin collecting data without any user-specific configurations. By leveraging the OPC UA infrastructure, the exchange of such industry-specific information models enables interoperability at the semantic level. This translates into faster integration and configuration of machines into existing production environments.

A sub-component of the OPC UA IoT Agent, known as the Mapping Tool, has been reengineered to facilitate the automatic discovery of OPC UA nodes and recognize OPC UA Companion Specifications, this enables a headless setup of the OPC UA IoT Agent. Additionally, the OPC UA IoT Agent has been extended to provide comprehensive support for OPC UA events propagation.

As a result, OPC UA events and changes in objects are disseminated to the FIWARE Orion Context Broker. The O2K-Connector subscribes to the FIWARE – Orion Context Broker to further transmit the ingested data to the message broker. To further improve processing times, the O2K-Connector has been developed to fully support both HTTP and MQTT subscription methods, with the latter significantly outperforming the former.

The OPC UA IoT Agent allows the straightforward and accessible retrieval of real-time data from industrial OPC UA machines, even for non-experts such as BIESSE. It seamlessly streams this data to market-standard data distribution platforms, unlocking numerous potential scenarios for cutting-edge data analysis, prediction, and monitoring.

In conclusion, the OPC UA IoT Agent elevates industrial efficiency by seamlessly connecting machines, simplifying data integration, and enabling smart decision-making and predictive maintenance.

Figure 2 . Architecture

Benefits & Impact

The IoT Agent OPC UA is a transformative solution carrying substantial promise for industrial users, with an impact that resonates across various fronts.

Currently, the IoT Agent OPC UA has amassed a considerable user base within the industrial sector. Numerous customers spanning various industries have already recognized its value, establishing it as a preferred choice for enhancing operational efficiency and data integration. This user base encompasses both small and medium-sized enterprises (SMEs) and large industrial players. Its adoption is not limited by the size of the enterprise but instead caters to a diverse array of industrial needs.

Looking ahead, the anticipated number of users is expected to grow substantially. The versatility and adaptability of the IoT Agent OPC UA position it as a future-proof solution. As industries increasingly recognize the significance of IoT and data-driven decision-making, it is likely that more users will turn to this solution for their needs.

The high impact of the IoT Agent OPC UA primarily resonates with industries striving to harness the power of the Industrial Internet of Things (IIoT). Sectors such as manufacturing, energy, logistics, and healthcare are poised to experience significant benefits. These industries deal with complex machinery and data-intensive processes, making seamless IoT integration essential for enhancing efficiency, achieving cost savings, and maintaining competitiveness.

This solution also holds significant importance for Europe, as it is being actively used in multiple Horizon 2020 R&D projects. These projects aim to advance European industries by incorporating cutting-edge technologies, and the IoT Agent OPC UA plays a central role in achieving these objectives. Its significance extends beyond individual companies, serving as a key contributor to the growth of the European industrial landscape and, consequently, the betterment of society as a whole. By facilitating efficient data exchange and integration, the IoT Agent OPC UA fosters innovation, competitiveness, and sustainability, aligning with the broader objectives of the European Union’s Horizon 2020 initiatives.

Added value through FIWARE

FIWARE have needed utilising for an extended period, harnessing the advantages of this innovative technology to enhance solutions. FIWARE, with its Open Source and Standards-based approach, has consistently delivered substantial value to our endeavours.

FIWARE has empowered the pilot to seamlessly achieve interoperability and scalability. Its standardized NGSI (Next Generation Service Interface) data model facilitates the integration of various data sources and systems, streamlining the process of collecting, processing, and sharing information. This interoperability ensures that our solutions can adapt and grow alongside evolving technological landscapes, future-proofing our investments.

One of the key value-adds created through FIWARE is the capacity to unlock the full potential of data. FIWARE’s context management capabilities allow us to not only collect data but also contextualise it. This means that data is not just a collection of numbers but is imbued with meaning, enabling smarter decision-making and deeper insights. Additionally, the ability to dynamically manage context ensures that our solutions can adapt to changing conditions and requirements in real-time, leading to increased operational efficiency and an improved user experience.

Furthermore, FIWARE’s ecosystem offers a wide array of pre-built, reusable components and enablers. This expedites development, reduces costs, and mitigates the complexity of building and maintaining our solutions. The rich ecosystem also fosters innovation by providing a foundation upon which developers can rapidly prototype and deploy new features and services.

FIWARE’s future readiness is another compelling reason why it is not only the right technology for current pilot but also for future solutions. Its active engagement in European initiatives like Horizon 2020 ensures that it remains at the forefront of technological advancements. FIWARE’s commitment to open standards and continuous evolution ensures that it can seamlessly integrate emerging technologies such as IoT, AI, and blockchain, making it a versatile and future-proof choice for projects and solutions. In essence, FIWARE serves as a reliable and innovative partner, consistently adding significant value to our efforts and positioning us for success in the rapidly evolving digital landscape.

Next Steps

To enhance the functionality of the system, we have planned some important updates. First, we have decided to expand the list of supported OPC UA Companion Specifications for automatic recognition. We will also address any identified bugs and make various improvements based on feedback from other validation scenarios. These measures ensure that the system becomes more robust and reliable.

These updates contribute to the overall effectiveness and usability of the system, facilitating smoother integration with industry standards and delivering a more refined and optimized solution.

Manfredi Giuseppe Pistone

Software Development Specialist

Walter Domenico Vergara

Software Development Specialist

Gabriele De Luca

Technical Manager

Cinzia Rubattino

Project Manager

Angelo Marguglio

Head of Digital Industry R&I Unit